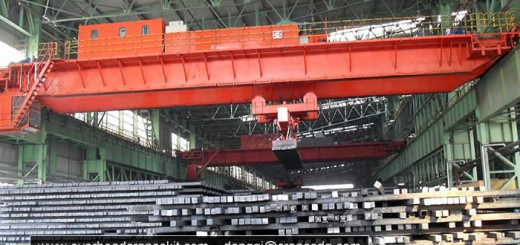

100 ton overhead crane for sale

As a type of heavy duty overhead crane, 100 ton overhead crane can lift heavier materials than the common. In many cases, the 100 ton overhead crane refers to the double girder overhead crane, which owns higher working duty and bigger working ability. There are two different hung types related to 100 ton overhead crane. The under hung overhead crane can maximum use the factory space and reduce building cost largely. While the top running overhead crane is widely used in place without limit.

100 ton overhead crane parameters

Lifting capacity: 100t

Span length: 10.5-31.5m

Lifting height: 6-20m

Working duty: A7

Ambient temperature : -10~50℃

100 ton overhead crane parameters

Lifting capacity: 100t

Span length: 10.5-31.5m

Lifting height: 6-20m

Working duty: A5, A6

Ambient temperature: -20~40℃

100 ton overhead crane parameters

Lifting capacity: 100t

Span length: 10.5-31.5m

Lifting height: 6-20m

Working duty: A5, A6

Ambient temperature: -20~40℃

QD type double girder overhead crane parameters

Lifting capacity :5-320t

Span Length: 10.5~31.5m

Lifting Height: 6~18m

Working Class: A5, A6

Ambient Temperature: -20~40℃

QD type double girder overhead crane parameters

Lifting capacity :5-320t

Span Length: 10.5~31.5m

Lifting Height: 6~18m

Working Class: A5, A6

Ambient Temperature: -20~40℃

QL type overhead crane with carrier-beam parameters

Lifting Capacity: 1~350t

Span Length: 6~45m

Lifting Height: 3~60m

Lifting Speed: 7.8-15.5m/min

Crane Speed: 20-30m/min

Working Class: A3-A7

Popular choice for Dongqi Crane’s 100 ton overhead crane

During more than 70 year’s growing, Dongqi Crane Company has development into the largest manufacturer and the biggest supplier in overhead crane industry. With professional engineer team and rich experience, Dongqi Crane Company is able to produce a wide range of bridge crane which contains the single girder overhead crane, double girder overhead crane, and some specific using overhead crane, like explosion-proof overhead crane and founder overhead crane. We can also manufacture various hoists of high quality to meet all your requirements. Additionally, our technician also can provide perfect solutions on design, installation and maintenance of your magnetic overhead crane. We also accept custom, and can produce satisfied material lifting to meet all your needs.

The two different manipulate ways of 100 ton overhead crane

There are two main manipulate methods of 100 ton overhead crane. One is ground operation which includes remote radio control and handlebar operation. And another is the cabin operation contains cam control and linkage control.

First, handlebar operation refers to people follows the track of trolley. It can not only monitor the driving trolley efficiently, but hung objects conveniently. Besides, handlebar operation can also save labor and time. However, compared with other manipulate means, handlebar operation exists a litter dangerous when people go with trolley.

Second is the way of remote control. On the one hand, people needn’t go with the trolley when lift big and hazardous materials. On the other hand, worker’s horizon will be limited on some level under this condition.

Third is the air control, also named cabin operation. The worker can own a broad vision though it. In addition, one important point when using this way is that it need special operation to match with the work of other people.

Then you can choose one most appropriate way according to your materials. Usually, it is better both use air control and remote control. Because, it doesn’t impact your production system when one fail to work.