Crane Parts: crane wheels

Crane Wheels Introduction

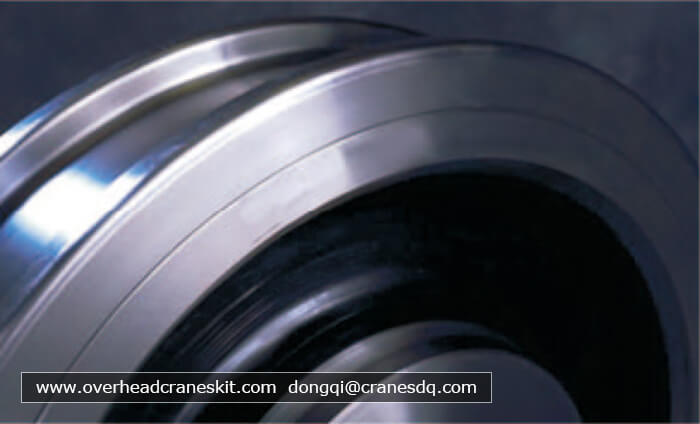

Crane wheels are replaced because of flange wear, flange breakage, and mechanical overloads characterized by pitting and spalling. Each of these inservice factors must be carefully considered before the combination of wheel design, material selection, hardness pattern and heat treating technology is selected.

Crane Parts: crane wheels

That’s why every Dongqi hardened steel crane wheel is specially designed and heat treated to maximize its resistance to the damaging forces at work in heavy industrial applications.

Dongqi Crane Wheels are

- Manufactured from fine gain, fully killed, vacuum degassed forged medium carbon steel

- Heat treated using our in house processes to provide a uniform contour hardness in the tread and inner flange wear surfaces, while maintaining a ductile core to resist shock loads

- Resistant to flange fracture or wear

- Designed to resist pitting and spalling

Advantages of Dongqi forged Crane Wheels

- Reduce maintenance cost of your wheels and wheel assemblies

- Improve the life of your rail

- Provide an additional 40% load carrying capability over rim toughened wheels

- Delivery in 6-8 weeks, less when required

Applications

- Overhead cranes

- Gantry and portal cranes

- Transfer cars

Forged crane wheel

Forged Steel Crane Wheels are available in a wide range of standard sizes. In addition, crane wheels to meet your special

design requirements can be produced in virtually any size, configuration and surface finish condition. We maintain a large

inventory of carbon and alloy steels to meet your specific needs.

Crane Parts: crane wheels

Forged Crane Wheels are available in any surface hardness up to HRC50 including our standard heat treatments.

Crane wheel sets

Crane wheels sets are available in different versions, either as a completewheelset or single wheel body available.

Crane Parts: crane wheel

Crane Wheel Assembly

We hold industry knowledge to manufacture Crane Wheel Assembly. These are ideal to bear the load of the crane or hoist for balancing. We severely follow the necessary quality standards and use higher tools and technologies in the process of manufacturing these products. Our variety is widely appreciated for quality, durability, adequate casting and efficient consequences. The complete product variety can be availed by our customers at market leading price.

Our crane wheels meet the standard JB/T 6392.1-92.

Wheels Processing

Our forging press provides the power necessary to achieve the dramatic reduction ratios and material flow which are essential in high quality forgings. This closed-die design provides excellent strength-toweight ratios necessary for your most critical forging needs. We stock a wide variety of carbon and alloy steels to meet your needs.

Crane Parts: crane wheels processing

Wheel blanks that we manufacture are used in a wide range of heavy duty applications including locomotive traction drives, wind turbines, speed reducers, and mining machinery.

Once the die cavity is filled, the pressure is intensified to ensure the elimination of any microscopic porosity that may have existed as a result of the casting process. This provides an extremely uniform and homogeneous grain structure in the forging. This contrasts with cast wheels which will always have some porosity caused by shrinkage of the steel during solidification. The grain structure and directional orientation of flow lines produces greater yield and tensile strength and other physical properties than can be achieved in a cast wheel.

Heat treating can significantly enhance the mechanical properties of a forging by imparting specific hardness, strength, and wear characteristics to meet the requirements of the application. A wide variety of heat treating capabilities are at our disposal to meet virtually any application.

Rough machining

Crane Parts: crane wheels

To realize the rough machining of the outer and inner contour surface of wheel blank,and clean up the spare parts of the blank quickly.

Quenching and tempering

Crane Parts: crane wheels

Quenching and tempering is widely used as our heat treating capabilities. It is designed for maximum flexibility by allowing us to heat treat a wide variety of materials, diameters, thicknesses and bore sizes. We are now able to provide virtually any heat treatment for carbon and alloy steels. This quench and temper facility is most applicable to gear blanks, rollers and miscellaneous forgings in specialty applications.

Fine cars

At raw materials receiving, steel ignots are inspected for proper identification. Certified test reports are required with each heat of steel. During cutting, heating and forging each block is carefully monitored for identification of material grade and heat

number.

Factory test

Crane Parts: crane wheels test

We have a wide variety of analytic tools and testing equipment available. A metallurgical laboratory is maintained on premise to perform chemistry verification, tensile and yield tests, and grain size verification. We also have Level III technicians available to perform ultrasonic and magnetic particle testing. These people and equipment are able to make customer required N.D.T inspections that eliminate the possibility of any surface or sub-surface defects.

From raw material to final inspection and shipping, we maintain a thorough quality assurance program to meet the most demanding customer requirements. Before delivery wheels, we will provide material report, heat treatment report, dimension report and hardness test report.

Coating

Crane Parts: crane wheels coating

Applications

Crane Parts: crane wheels applications