Crane Rail Wiki: Crane Rails Classification and Installation

Overhead cranes and gantry cranes run on the rails. So if you want to purchase overhead crane or gantry crane, it’s a good idea to know some crane rails knowledge.

Crane Rails

Crane Rails Classification

There are special rail, rail track, square rail and P-type track; the square rails wear on the wheel is relatively large, now is rarely used; no matter cranes or trolley,P-type rails are widely used.

The top of the rail is convex, the bottom is a certain width of the plate, an increase of the contact surface with the base; track section for the I-shaped, with good bending strength. Square steel can be seen as flat-top rail, due to wear on the wheel, generally only for the smaller weight, slower speed, the work is not frequent cranes. The rails are usually rolled with carbon and manganese higher steels (C = 015% to 018%, Mn = 016% to 115%). The typical material of the crane rail is U71Mn steel. Square steel is mainly made of Q275 square steel or flat steel.

Crane rail is used for cranes and trolley with special cross-section rail, the standard length of 9,915,10,1015,11,1115,12,1215 8 kinds of. Common specifications for the QU70, QU80, QU100, QU120, QU behind the number of said track head width. Railway rails are divided into two kinds of heavy rail and light rail, rail size with a nominal weight per meter length. Weight greater than 30kg / m of rails, are heavy rail. Standard rail length of 12150m and 25100m2 specifications. Light rail not more than 30kg / m of the rail, usually the length of 5 ~ 12m. In order to improve the wear resistance and corrosion resistance of steel rails, low-alloy structural steels such as Mn, Si and P alloy elements have been used in recent years.

How to choose the suitable crane rails

|

Wheel Dia(mm)

|

200

|

300

|

400

|

500

|

600

|

700

|

800

|

900

|

|

Crane Rails

|

/

|

/

|

/

|

/

|

/

|

QU70

|

QU70

|

QU80

|

|

Rail Track(Model)

|

P15

|

P18

|

P24

|

P38

|

P38

|

P43

|

P43

|

P50

|

|

Square Rail

|

40×40

|

50×50

|

60×60

|

80×80

|

80×80

|

90×90

|

90×90

|

100×100

|

|

P-type Rail(Rim(mm))

|

40

|

50

|

60

|

70

|

80

|

90

|

90

|

100

|

Crane Rails Installation

Crane Rails Installation

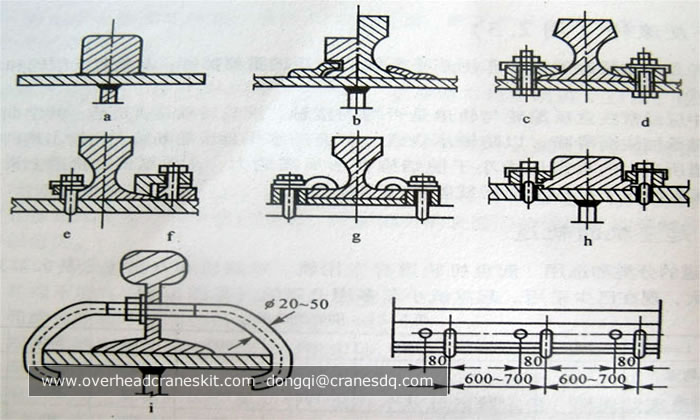

Crane track in the main beam on the main fixed in the following ways:

1, a using continuous welding, non-removable structure, the track section force can be included in the total force of the main beam, an increase of the main beam of the bearing strength, for the work level M5 following the car track.

2, b diagram is the most commonly used fixed method, easy assembly, but the demolition of more trouble.

3, c and d are applicable to the working level M6, M7, M8.

4, e and f diagram using a screw connection for the bottom of the bolt is not easy on the special circumstances.

5, g in the bottom of the track pad thickness 3-6mm rubber, can reduce the impact.

6, h is the ring track fixation method.

7, i is fixed on the crane rail carriage rail beam on the way.

Crane Rail Safety and Adjustment

- the track safety checks: check the track, bolts, splints without cracks, loose and corrosion. Found cracks should be replaced in time, if any other defects should be promptly repaired. The main inspection tool with line track flaw detector.

- the track measurement and adjustment:

(1) the linearity of the track, the method can be used to check the pull wire, that is, both ends of the rail car pull up a 0.5mm wire, and then use the hanging line hammer method to point by point measurement, measuring point interval of about 2m .

(2) the elevation of the track, the level can be measured.

(3) track span, can be used to measure the tape or infrared measuring instrument inspection. Bridge crane gauge allowable deviation of ± 5mm; track longitudinal gradient of 1/1500, two orbit relative elevation allowable deviation of 10mm.

(4) track joints, the track can be made of direct head, can also be made of 45 ° angle of the joint. Miter joints allow a smooth transition of the wheel at the joint. General joints of the gap is 1 ~ 2mm, in cold regions should consider the impact of temperature on the gap, generally 4 ~ 6mm. The height difference between the two tracks at the joint shall not be greater than 1 mm.

Please i need quote for track rail for gantry Crane