DHD Series Heavy Duty Double Girder Overhead Crane for your factory

Heavy duty %&&&&&%

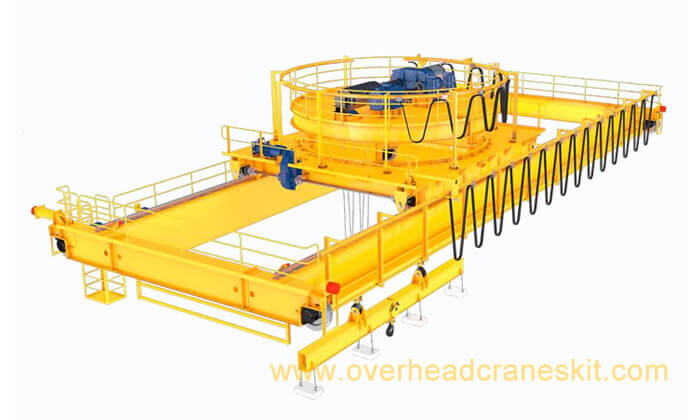

Heavy Duty Double Girder Overhead Crane Overview

Advanced Technology & Reliable Application

Together with industry experience, combined with advanced technology, new heavy duty overhead crane is the new generation product of Dqcranes. All of our innovation is incremental, and is marketed based on strict testing and successful operation experience, therefor our customers can choose the products of this series safely.

This kind of cranes can be applied to all kinds of industry factories, such as papermaking industry, power industry, garbage power generation industry, steel industry, petrochemical industry, metallurgy casting industry and so on.

- Lifting Capacity: 5~320t

- Span: 7.5m~35.5m

- Lifting Height: Customized

- Working Class: A3, A4, A5, A6, A7, A8

Heavy duty double girder overhead crane

Compact Structure & Modular Design

DHD crane is of mang features, such as compact structure, low dead weight, small wheel load, uniform load distribution and so on which will decrease the construction cost greatly, reduce heating cost and make the maintenance easily. This can optimize the comprehensive investment of customers ang help them to achieve larger rate of return on investment.

More Configurations & More Options

DHD crane can lift goods of 5 tons to more than 320 tons according to different configurations. It can also meet the personalized needs of customers based on different options, such as attachments for workpiece overturn, anti-swing devices, auto positioning, maintenance supervision, remote fault diagnosis and so on. We will offer personalized and professional solutions for our customers with our professional experience and advanced technology.

DHD crane is easy to renew and expand, even though after the delivery of products. Customers need more function options and configurations which can all be solved by us. It is a product which sees long future.

Heavy duty double girder overhead crane

Safe, Reliable and Easy to Maintain

Equipped with advanced technology, advanced processing equipment, series of production and strict quality control, Dqcranes ensures the high quality and good performance of DHD crane.

In design aspect, we adopt non-maintenance + easy maintenance to ensure the product advantages and at the same time, make the customer convenient to maintain and easy to master.

Heavy Duty Double Girder Overhead Crane Performance

In General

European standard (DIN/FEM) optimized design, light dead weight, small wheel load, small volume

Max. lifting capacity: 320t

Flexible solution for all lifting needs

Excellent driving properties, stepless control, smooth moving

Heavy duty double girder overhead crane

Mechanical Feature

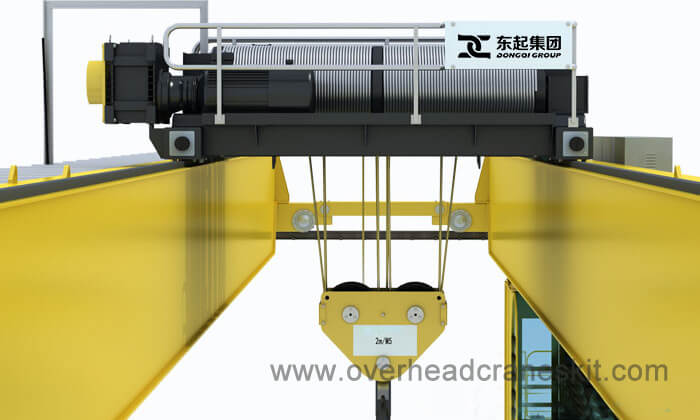

Double welding box girder, beam deflection with DIN/FEM standard

Steel Material: Fe37 or Fe52 (Equal to Chinese standard Q235B and Q345B)

Whole length CNC cutting for complete web plate, to ensure the precision and smooth curve shape of the camber

Trolley rail is made of high strength hot rolled flat steel (16 Mn)

Automatic submerged arc welded main weld with NDT inspection

Shot-blasting Sa2.5 for complete girder after welding, to achieve stress release

Epoxy zinc-rich painting for one bottoms and two sides of 120μm thick, to achieve a long lifespan, beautiful appearance and good luster

The girder and end beam are connected together by Class 10.9 high strength bolts to ensure the structure strength and precision of the whole machine

Trolley and crane are driven by Three-in-One driving mechanism, variable frequency speed regulation, the hard tooth face, electromagnetic disc brake

Protection class: IP54, Insulation class: F, electrical sustained rate: 40% ED

The end beams are equipped with flat wheel or double rim wheels, anti-friction bearings, buffer blocks and derailment preventing end plate

Maintenance walkway is located on one side of the main girder, consisting of pattern plate, armrest (Height: 1050 mm), pillar and toe protection

Heavy duty double girder overhead crane

Electrics

Power supply: Safety sliding contact line

Equipped with protection function in case of default phase

Hoisting, trolley and crane movements are controlled separately.

They can run simultaneously or independently.

Dedicated vibration control contactor for crane

The control panels are corrosion resistant, protection class is IP55

All the plug sockets are with heavy duty plug heads, reliable sealing and firm inserting

The layout of components in the control box is reasonable, easy to maintenance

Plug connection parts are protected by insulating plastic casing

All cables are coded with numbers, easy to identify

The movement of trolley is powered by insulated PVC flat cable which is specially designed for cranes, and stress level of it can reach to 450/750V

The mobile power supply system for trolley consists of flat cable, galvanized slides and small cable jigger to achieve smooth sliding

Lifting Mechanism

The most advanced lifting mechanism, good performance of maintenance free (Please refer to European style lifting mechanism-wire rope hoist)

Heavy duty double girder overhead crane

Safety Protection

Anti-falling protection for the Three-in-One electric motor of trolley and crane prevents from accidental falling

Rain Cover: For lifting mechanism of outdoor cranes, electric cabinet and driving mechanism

Acousto-optic alarming device

Wireless anti-collision device

Control Mode

Pendant

Easy to control, no additional driver necessary

Double block button to achieve safety stop

Following type or independent sliding type suspended under hoist

Protection class IP65

Lifespan: 500,000 times

Remote Control

Easy to control, no additional driver necessary, to operate more freely on the ground

Tens of Thousands of frequency points, non-interference with each other

Two steps push button or joystick station with emergency stop

Protection class IP65

Lifespan: 500,000 times

Cabin Control

Linkage control, conjoined with driving chair, easy to operate

Professional driving chairs, adjustable and fully turning

Round window with large arc glass, wide view

Two steps push button or joystick station with emergency stop

Heavy duty double girder overhead crane

Heavy Duty Double Girder Overhead Crane Parameter

| Service Type | Indoor | |

| Height above sea level | <1000 | |

| Load | t | 50/10 |

| Span | m | 12 |

| Lifting height | m | 6 |

| Main hoisting speed | m/min | 0.42~4.2 |

| Aux. hoisting speed | m/min | 0.9~9 |

| Trolley traveling speed | m/min | 20.8 |

| Crane traveling speed | m/min | 3.2~32 |

| Power supply | 380V 60Hz | |

| Crane working class | A6 | |

| Hoist working class | M6 | |

| Electric hoist service rating | Kw | 2.6×2 |

| Crane service rating | Kw | 4.8×2 |

| Main Lifting motor rated output | Kw | 37 |

| Aux. Lifting motor rated output | Kw | 22 |

| Total power | Kw | 73.8 |

| Wheel diameter | mm | 315 |

| Groove width | mm | 90 |

| Hoist and trolley weight | Kg | 10500 |

| Total weight | Kg | 22000 |

| Max. wheel load | KN | 153 |

| Min. wheel load | KN | 44.5 |

Looking forward to receive your enquiry with the below details information

- Lifting capacity

- Span ( rail centre to centre )

- The required lifting height ( from hook to the ground )

- Crane travelling length

- What will be lifted by the crane

- The crane and hoist movement speed (m/min)

- The rail length and the height.

- Single speed or double speed for lifting and travelling?

- Driver cabine control or pendant control?

- How many hours work per day?

- Power source: 380v, 50Hz, 3phase or others?

Please leave your inquiry in the comment box or send it to [email protected].