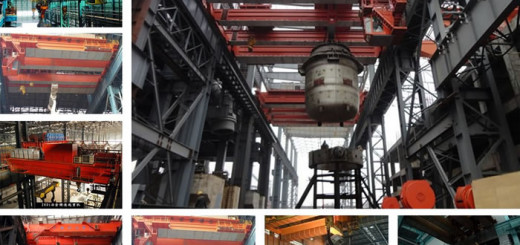

Dongqi Double Girder Overhead Bridge Crane with Electric Hoist, for Lifting Heavy Duty Materials

Double Girder Overhead Crane

Key Specifications/Special Features

Design, features and specifications:

Widely used heavy duty light weight LH overhead crane is used when heavier loads, wider spans or higher working frequency are required

Double girder cranes consist of two torsion-free box girders

This makes double girder cranes suitable for lifting and transporting loads over 10T and for span of more than 25m

Double girder overhead cranes are available with load capacities up to 100T and with spans up to 50m

Heavy duty end carriage joints ensure positive contact of all four wheels with the track

The profiles of the main girder are optimally produced using an integrated technology which is weldless, so that maximum performance with a minimum of dead weight can be achieved

Optional features:

Variable speed through VVF drive

Soft starter

Slip ring motors

Wireless radio remote control

Shrouded DSL system for power feeding

Flameproof

Cabin operated

PLC automatic control system

Advantage:

1). Compact design, optimal use of the work areas

2). Heavier loads, wider spans and higher working frequency

3). Control the load easily, position the load exactly

4). Superior safety and reliability

5). “One-stop shop” for your crane and hoist needs

Safety:

Overload protection

Main lifting motor with thermal protection

Hooks with latch

Rubber buffers

Protective earthing

Emergency switch

Sub-assemblies characteristic are tested before assembly

All cranes must be preassembled and tested before leaving factory and offer the certification of test

Standard features:

Design:

Motors: the motors are used specially crane duty suitable for frequent starting, reversing and braking in accordance with ISO 9001:2000 ISO 14001:2004

Brakes: independent hydraulic brake make the crane safer and easier to control

Gear box: the entire gear boxes are made of accurate hob cut helical/spur gears and pinions having hardness 250 to 350 BHN made from carbon alloy steel

Wheels: the wheels of crane crab, main beam and end carriage are produced in our special vacuum casting workshop (no sand inclusion technique) which makes our wheels more elastic and outer surface hard-wearing and durable

Electrical panel: nodular design, ease to install and maintain, reliable operation, fuse less circuitry, ducted wiring and compact terminals, motor overload protection to prevent overloading

Limit switch: safety limit switches for stoppers will be provided to prevent over traveling in all motions

Painting: two coats of primer before assembly and two coats of synthetic enamel after testing