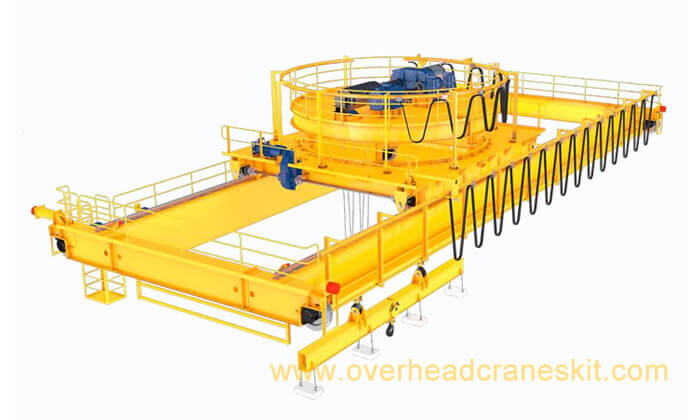

Dongqi Electric magnetic beam crane, special for steel plate with 1 or 2 trolley

Electromagnetic overhead travelling crane

Key Specifications/Special Features

- Introduction:

- Low level slewing overhead crane with carrier beam

- The crane has slewing carrier beam, is applicable to the fixed span at indoor or outdoor of steel mill, shipyard, port, yard and storage

- It is used for loading, unloading and carrying steel plate, profile steel and spool

- It is specially applicable to lift material of different specifications and which needs horizontal rotation

- The carrier beam is cross structure, which is reliable and has good safety features and has a certain function of preventing swinging

- The lower part of the carrier beam can bring special lifting appliances, such as magnetic chuck and tongs

- The electric magnetic hanging beam double beam overhead crane is made of welded steel plate and reinforcing sections

- It is equipped with motor, gearbox, cable, wheel, handing beam, hook, spring buffer, anti-collision system, cabin control system with handle type remote control system, SEW brand motor and gearbox for traveling, and ABB brand motor for hoisting, Yakawa brand frequency inverter for the all motion and others

- The main function is to hoist the steel billet from CCM yard to warehouse or other place

- Details:

- Capacities: 10 + 10 to 13.5 + 13.5 or customized

- Maximum span: as per your needs

- Maximum lifting height: as per your needs

- Working duty: up to A7

- Working temperatures: -40 to 60°C

- Motor: Nanjing special motor number 1 in China for crane

- Gear box: SEW three in one type

- Electric parts: SIEMENS brand

- Safety:

- Overload protection

- Main lifting motor with thermal protection

- Hooks with latch

- Rubber buffers

- Protective earthing

- Crane switch and travel end switch

- Emergency switch can stop all movement when any dangerous happened

- Sub-assemblies characteristic are tested before assembly

- All crane must be pre-assembled and tested before leaving factory and offer the certification of test

I’m looking for a magnet system to handle 12m long x 2.44m wide steel plate, from 6mm to 32mm thick. PLease send a quote and more technical information