Gantry crane installations for the Saudi Electricity Company

Gantry crane installations finished successfully for Saudi Electricity Company(“SEC”) company in September.

5 tons single girder gantry crane installed in Saudi Arabia

Gantry crane main parameters

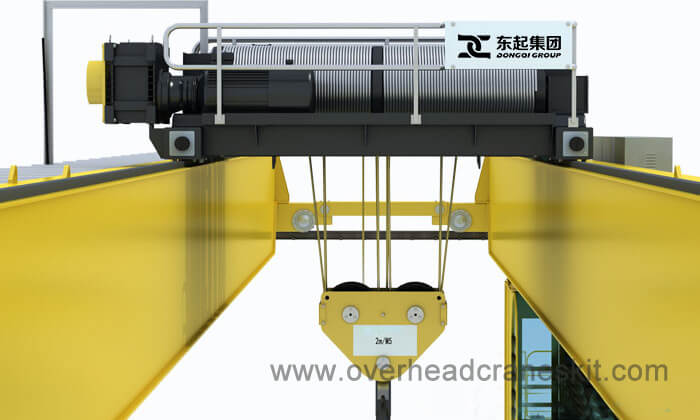

- Type of crane: Single girder electric gantry crane

- Lifting capacity: 5 tons

- Lifting height: 16 meters

- Span: 30 meters

Customer profile

The principle activity of Saudi Electricity Company (“SEC”) is the generation, transmission, and distribution of electricity within the Kingdom – the largest economy in GCC. It is the leading producer of electricity and sole owner of the entire transmission and distribution network throughout the Kingdom, serving all types of consumers. The Saudi government owns a majority of Saudi Electricity Company’s shares.

Saudi Electricity Company

Single girder gantry crane installation procedures

How the single girder gantry crane installed? In the part, the on-the-spot report will be digested for your reference.

Work out the installation plan for the gantry crane

When we met the customer, we go to gantry crane installation site with customer. And then made one plan how to install the single girder gantry crane and how many days do we need to finish the job and others.

- The process how to install the gantry crane:

Install the rail

Connect the end carriages and bottom beam

Set up the legs

Lift up the main girder and installed the hoist

Put down the main beam on the legs

Electrical works

- 15 days estimate time to finish the installation of the gantry crane.

- Installations workers and tools

Workers required:

2 welders at least

4 mechanical workers and 2 electrical workers

1 driver to control the 30tons truck crane

1 driver to control the boom lift/scissor liftTools needed:

4.0 lever weld rod

4 chain blocks with 1ton capacity at least

Tools box, including the wrench, spanner, screw driver, welding machine and others

After confirm the above details, we start the work directly.

Gantry Crane installation implantation

Rail installation

Gantry crane rail installation

Then we installed the four side rails for gantry crane with the help of workers.

As for the 5tons and 30m/20m span gantry crane, wheel load is heavy, so we choose the P38 rail for customer.P38 rail is fixed on ground by platen and clamp by bolts.

After this process finished, we begin to connect the bottom beam and legs.

Bottom beam and legs connections

Gantry crane bottom beam and legs connections

Firstly you have to know there are two bottom beams and four legs for each crane. It means one bottom beam shall connect two legs.

Connections by bolts also.

Put the bottom beam down on the ground with enough spaces, then lift the legs up and moving it slowing towards to the bottom beam directions. When you keep the hole between the bottom beam and legs at the same spot, use one steel stick to hold it and connect all the holes soon by the bolts. After all holes were connected by bolts, try to shake it to check whether the connection is steadily .If ok, then do another one leg.

Then the engineer has to ruler the distance between the two legs. This distance shall be same with the saddle of main girder.

If distance is ok, then find one box iron to weld it on the legs to make sure the distance steadily when it was lifting up.

Lifting and setting the legs up on the rail

Install gantry crane legs on the rail

After connect the two sides legs and bottom beams, we have to set the girders up on the rail. It would be good to choose one small wind day to set up legs.

Finding the center of box iron which was welded already on the two legs and using the truck chain to fix it, then lift it up and put it down on the rail slowly.

After the left two legs were lift up, we have to use the wire rope and chain to fix the center of box iron also. One left two legs need two chain block fix on each side. If this finish, then another one.

Fix the hoist on the bottom of main girder

Let the truck crane lift the main girder up and keep about 1.5 meters distance up from ground. Ship the hoist to the bottom of main girder and fix it tightly.

Connect the cables and limit switch etc

Lift and fix the main girder on the top of legs

Install gantry crane main girder on the legs

We have to use the truck crane to lift main girder up slowly and we have to find two person at least to climb to the upside of legs when there is one good position between the legs and main girder. The two person of each side have to make sure the main girder edge is in the side of the bolts. Then put it down and let the welder to weld the girders and legs. We have to weld at least two spaces of each connection sides before we remove the truck crane.

After all the weld finished, it means all the mechanical works finished.

Electrical works

Install gantry crane electrical equipment

The engineer will guide the workers do the electrical workers to do the electric with the help of boom lift.

After all the mechanical works and electrical works finished, we test and commissioning the crane.