1-80 ton European-spec Electric Hoist

ND Electric Hoist Overview

ND Electric Hoist is designed on the basis of advanced electric hoist, with high degree of intelligence. It is with advantages such as light weight, low height, sophisticated configuration, high transmission efficiency, low noise, energy saving and environmental protection, etc. ND Electric Hoist adopts modular design, with high degree of universalization of all parts, high maintenance-free rate, less wearing parts.

Dongqi Crane is professional material handling equipment manufacturer and servicer with largest production in global. Provide you with overhead crane, gantry crane, electric hoist, etc. of safe, reliable and efficient crane solutions and services.

ND Electric Hoist Features

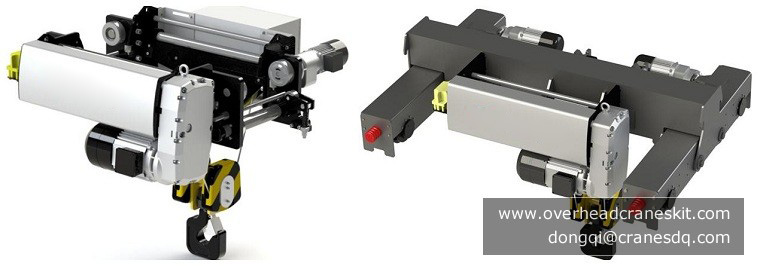

The overall layout of ND Electric Hoist is parallel C-type structure, compact, good force location, installation and maintenance of motor and reducer both are very convenient. Adopt unique anti-wheel turning round design, reduced dimensions and hoist weight.

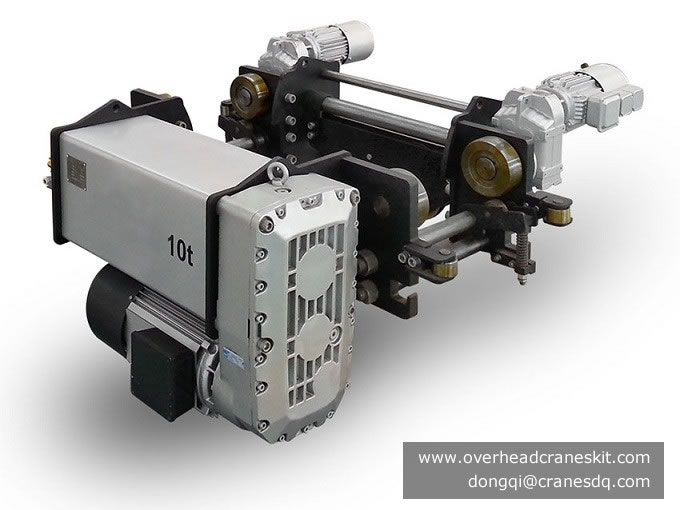

Three-in-one motor reducer

Lifting motor using original imported German crane specific products. Motor for low vibration, low noise design of squirrel cage cylindrical 2/12 pole two-speed brake motor to achieve lifting speed of 6: 1 of fast and slow two speeds, fast and slow speed conjunction reached on the true meaning of operation fast and easy and accurate positioning. Motor connected power sustained rate of not less than 60%, F class insulation, motor protection class not less than IP55, and has overheat protection and alarm functions, motor housing made ??of aluminum alloy drawing molding, excellent heat dissipation. It can also adopt 4-pole inverter motor in accordance with the requirements, to achieve stepless speed, used in precision installation, with PLC programmable logic controller for anti-swing positioning and others.

Crane and trolley drive adopt advanced overall three-in-one drive mechanism, drive system with closed structure design, the transmission gear soaked in the lubricating oil during operation, in order to improve gear life and reduce noise. Reducer gears adopt 20CrNiMo low carbon alloy steel made through carburizing and quenching, gear grinding process, with the gear surface hardness of 60HRC or more, to achieve the requirements of hardened reducer requires, gear manufacturing precision reaches 7 class or more. With hardened surface, quiet design, good sealed, no leakage and maintenance-free design. Trolley traveling motor select squirrel-cage motor, motor protection class not less than IP55, connect power sustained rate not less than 40%. Adopt frequency control, reduce the impact of crane and trolley impact during braking, achieve the purpose of smooth traveling.

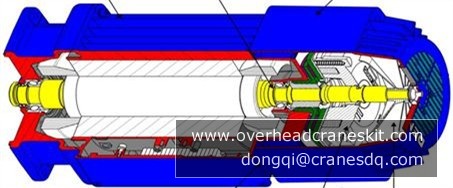

Brake System

ND Electric Hoist with maintenance-free electromagnetic chuck brake, braking during power off to ensure safety. Maintenance-free design that is after the brake block wear, the brake block thickness has the function of detection and alarm, brake block material is with environmental protection and is non-asbestos, electronic modular system built-in brake makes the brake fast and agile. Minimum brake safety factor of 1.8, safety brake not less than one million times.

Wire Rope

Hoisting mechanism wire rope adopt foreign production products in line with international standard, all made ??of galvanized wire rope, no maintenance or coated with anti-rust oil, breaking strength not less than 1960N / mm2, safety factor not less than 5.

Using original spring-wheeled guide rope device, which made of polymer composites, with high strength and good toughness. the force of the spring can automatically adjust the compaction degree of guide rope according to working conditions during operation, so that the guide rope completely becomes durable from quick wear part.

Crane Hook set

ND Electric Hoist hook is high strength grade T level hanging head, the material is quenched and tempered steel forgings 34CrMoV, can rotate 360 degrees, has prevent slippage safety buckle, hook block pulley using sheet metal roll forming, with good appearance and strong stress tolerance.

Safety Monitoring System

ND Electric Hoist device set with “black box”, can realize efficient operation status monitoring, repair and maintenance information display, troubleshooting and optimization of operating parameters.

The controller will conduct self-test before electric hoist starting, including the power supply voltage level, whether phase loss or not, validity of each safety device and button zero status.

Set electric hoist limit switch, overload limiters, etc.

Electrical control

ND Electric Hoist electrical components adopt Siemens, Schneider, ABB and other international brands, the mechanical life of more than one million times. With rational layout of electrical control box, clear line number, standardized and orderly wiring, and easy maintenance. External wiring using heavy duty aviation plugs, convenient to install, avoid mistakes.

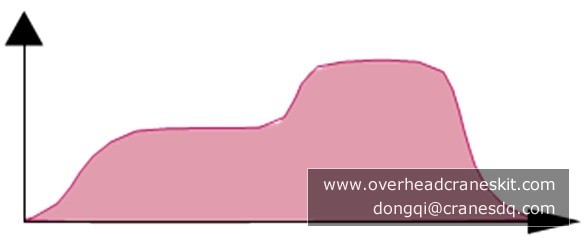

ND Electric Hoist traveling using variable frequency drive design, operation speed is 2 ~ 20m / min. Speed ??switching with smooth transition.

Variable frequency drive design most suitable for multi-changing traveling speed and high positioning accuracy required conditions, which can be used to obtain different speeds. It can adjust important parameters include acceleration and deceleration ramps by the controller. The transmission can achieve gentle start and braking, reduced the load swing to a minimum level. Suitable speed, without swing operation and sensor sensitivity positioning greatly reduce the work tempo.