Winch crane | overhead winch crane

Overhead winch crane for demanding lifting

Dongqi overhead winch crane are ideal for demanding material handling for they are for assembly and maintenance.

Features of overhead winch crane

Overhead winch crane are flexible enough for nearly all the industries for they are combined with the latest advanced design with hardy electronic and a sharp computer intelligent, ensuring the total control over your overhead crane and material handling.

- Up-to-date technology is used on the overhead winch crane which are intelligent and mart.

- The robust overhead crane and winch can be customized to your application conditions.

- The overhead winch cranes are widely used in different industries.

- With advanced technology, the overhead winch crane are faster, more efficient, and more safety.

- Various types of overhead winch cranes are available for your application with various types of winch available.

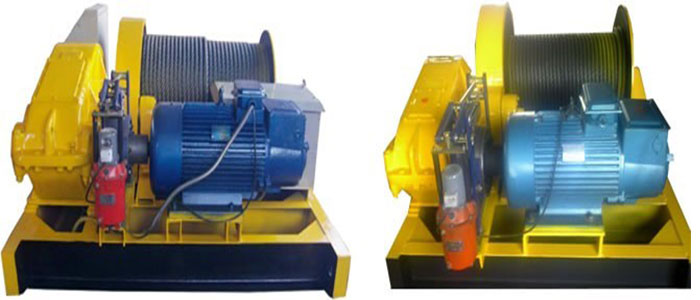

Winches for overhead cranes

Dongqi provide you various types of electric winches for your selection for your overhead winch cranes. Generally, the electric winches can be grouped into various types, such as, JM Series controlling slow speed electric winches, JK series electronic control high speed electric winches, JMM friction series electric winches, JK-D series electric winches and IKL series hand control high speed free rolling winches. Each type of electric winch has its own features and advantages, which can find their places in the various applications and performs

- JM Series Electric Winches

JM series electric winches is a gear reducer type drive type winch, which is mainly used for handling materials under 10 tons. JM electric winches can be used to hoist, pull, load and draw heavy weights. It also can be applied to various large and medium concrete structure and the installation and disassembly of mechanical equipment. JM Series Electric Winches are suitable for the civil construction and installation project in construction and installation company, mine lot and factory.

Features of JM Electronic Winches

- JM series electric winches is a type of a slow speed heavy tonnage winches.

- JM electric winch has an orderly arranged wire rope, providing safe and reliable material handling solution.

- JM electric winches can be widely used for road and bridge project, i.e. bridge, port, dock, and larges factories and mines, etc.

- JK Series Electric Winches

JK series electric winches is mainly used for handling heavy weights and the weight and it also can be used as the lifting mechanism of cranes. JK electric winch is specially designed winch for derrick, gantry frame, and lifting trolley. It is suitable for small equipment installation and assembly used in mine, factory, etc.

JK series electric winches

- JMM Series Electric Winches

JMM electric winches is usually used for long distance traction of various kinds of large and super concrete and steel structure, steel cable, etc. JMM electric winches is suitable for all kinds of bridge engineering, large factories, mine engineering equipment installation.

JMM electric winches

- JK-D Series Electric Winches

JK-D electric winch is a new type of winch which can be an ideal replacement of traditional hoist.

The JK-D electric winch has the features of small teeth difference, compact structure, small volume, smooth running, convenient and easy maintenance, low noise and a long service life.

JK-D electric winch is widely used in building construction, dock, bridges and metallurgical industries for lifting and installation.

JK-D electric winches

- JKL Series Electric Winches

JKI electric winches is mainly used for handling heavy weights in construction site, factories, mine, ports, especially in bridge dock construction base engineering free-fall punching piling operation.

JKI electric winch

How to use electric winches safely

Before start working, in addition to comply with the winch safety operation, electric winches should be test-run, inspect every parts and the operator should be familiar with the operation situation. Here is some instructions:

- The anchor bolts will be fixed or embedded anchor when the winch is installed. To avoid dragging the electric winch when working.

- Before using the electric winch, check all the parts carefully and whether the bolts loose, wire rope fastening degree and the lubrication conditions to every part, etc.

- The electric winch needs to be no-load test run for 15 minutes before working. Check each transmission part to make sure it has no shock vibration phenomenon, and the switches is sensitive, and the brake is flexible and reliable.

- Overload is absolutely forbidden during operation. The lifting capacity of electric winch is in the technical parameters range.

- Dynamic load test is exceed 10% of rated load of electric winch, repeatedly lifting several times. After testing, check whether the electric winch’s mechanical transmission, electric parts and connect parts are normal and reliable.

- During operation, prohibit cleaning or refueling, no person stand in front of the machine or under the heavy objects. Also notice the transmission performance of machine, to keep the transmission parts lubricated well.

- During operation, the operator should pay attention to the unfavorable conditions of wire rope on the drum at any time, and clean them in time. Strictly prohibit to use the hand to guide the wire rope.

- Electric winches should be operated by specialist, and inspect and maintain it regularly to avoid the damage caused by improper using. If find it out of order during working, the main power should be cut off immediately.

- When electric winch is not e working, the heavy object is not allowed to suspend in the air. The main power source should be turned off after working.

- Gear reducer oil level should keep above the oil level elevation line, reducer adopted 55-7 oil for lubrication. Change the oil every 2-3 months. And other lubrication parts refuel 2-4 times every shift.

- After half year’s working, inspect the reducer and change the lubrication oil, inspect the brake, motor and test the motor’s insulation resistance to ensure safety production.

Winch crane projects- Cases

- 10 ton electric winch with fast speed used for 40 ton gantry winch crane’s main lift mechanism for China railway construction company.

- 8 ton electric winch with fast speed used for 80 ton gantry winch crane’s main lift mechanism in the china three gorges corporation xiluodu project.

- 8 ton electric winch fast speed used for ZKL-800-30 auger driller.

- 5 ton electric winch fast speed used for ZKL-800-26 auger driller

- 5 ton electric winch fast speed used for Luoyang mining group.

- 6 ton winch crane used for Limekiln loading, Beijing Aiken.

- 3 ton winch crane used for Limekiln loading, Xinjiang Tianye.

- 5 ton winch crane for material handling in steel factory.

- 9 ton winch crane for material handling, Tangshan Steel.

- 5 ton winch crane for lifting Calcium Oxide.

- 5 ton winch crane for coking plant maintenance

- 10 ton winch crane for tensile steel strip coil rolling mill production line

- 5 ton winch crane for pulling flatcar in steel plant

- 6 ton winch crane for coking plant loaking material.

- 5 ton winch crane for Luoyang thermal power plant

- 5 ton winch crane for Waste steel recycle production line.

- 20 ton winch crane h for 380m furnace cleansing.

- JMY 5 ton mobile electric winch for pulling rib plate on shipyard.

- 2JK2011 ton winch crane for 350 ton ship lifting.

- 30 ton winch crane for shipbuilding company.

- 10 ton winch crane for Hydropower station.